Forklift Technical Information

The largest forklift operator training website in the world

![]()

![]()

Standards Applying To Forks And Carriage

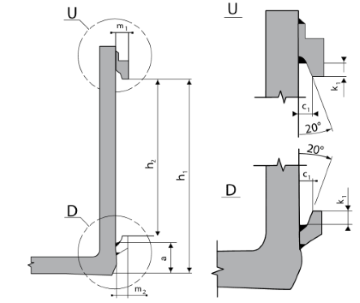

Fork carriage dimensions are subject to standards laid down by FEM/ISO so that fork manufacturers can all produce forks to the same standards from a dimensional point of view. The sectional drawing shown indicates the dimensions that are controlled by the standards, i.e. all of them!

Today the ISO/FEM-suspension is the most common way of connecting forks to the lift-truck world-wide. According to the rated truck capacity, the ISO/FEM-standard consists of five classes, each of them having a form A and B (e.g. class 2A or 2B).

The difference in the forms A and B is the fork drop (clearance lower hook to floor). All measures are defined in the international standard ISO 232

The five classes of fork carriage are dependant on forklift capacity and working load centre as shown below

- Class ! from 0 up to 999Kg forklift capacity at 400 mm load centre

- Class 2 from 1000 Kg to 2500 Kg forklift capacity at 500 mm load centre

- Class 3 from 2501 Kg to 4999 Kg forklift capacity at 500 load centre

- Class 4 from 5000 Kg to 8000 Kg forklift capacity and 600 load centre

- Class 5 from 8001 Kg to 10,999 Kg forklift capacity and 600 mm load centre

The standards for forks obviously follow the same dimensions as those for fork carriages. Most forks are designed to "hook on" to the carriage and to this end the carriage has a slot cut in the middle at the bottom to allow for attaching and removing the forks.

The standards for forks obviously follow the same dimensions as those for fork carriages. Most forks are designed to "hook on" to the carriage and to this end the carriage has a slot cut in the middle at the bottom to allow for attaching and removing the forks.

As a final point it's worth pointing out that there are several variations to forks as some, for example those used on telehandlers, have bar type fitting where the top of the fork is forged into a circular section which is then attached to the telehandler by a horizontal bar. Forks can also be manufactured for special applications. One example of this are "chisel forks" which taper all the way along their length effectively creating a very thin fork tip which can then be used to "chisel" into certain types of loads. Whatever the design, the dimensions shown below remain constant.

Mast Assembly | Mast Critical Dimensions | Lift Cylinders and Chains |