Complete Powerpoint slide presentation for forklift instructors. Ready made training course

Aisleway dimension calculations for reach trucks

It might be useful to read the section on counterbalanced forklift truck's aisleway dimensions before reading this page.

It might be useful to read the section on counterbalanced forklift truck's aisleway dimensions before reading this page.

Reach trucks can work in much smaller aisleways than counterbalanced trucks saving maybe as much as a third on aisleway space.

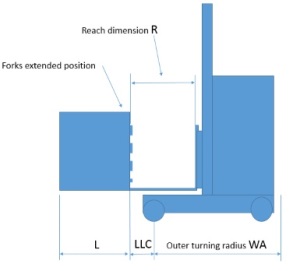

The aisleway dimension calculations are similar to the counterbalance ones but the truck's reach distance must be taken into consideration. The calculation is shown as:

WA+LLC-R+L

where

Wa = The forklift truck's outer turning radius

LLC = Reach truck's lost load centre

R = The reach distance

L= Length of load

(The lost load centre is the horizontal distance from the centreline of the reach leg wheels to the front face of the forks with the mast fully reached out).

As with counterbalanced forklift trucks whilst this gives the theoretical minimum ninety degree stacking aisle dimension it does NOT take into account any room for real life operator clearance.

Again many manufacturers do not allow for this on their specification sheets so a clearance must be added for the operator. The ABA test uses 23 cm, (9 ins) and this should be regarded as a minimum for trained and skilled operators. Larger dimensions will increase productivity and lead to safer operation.

To recap, the minimum distance between racking uprights should be:

WA = Forklift truck outer turning radius plus

LLC = forklift truck's lost load centre minus

R = Reach distance plus

L = Length of load plus

23 cm, (9 ins)

Click here for counterbalanced forklift truck aisleway calculations.